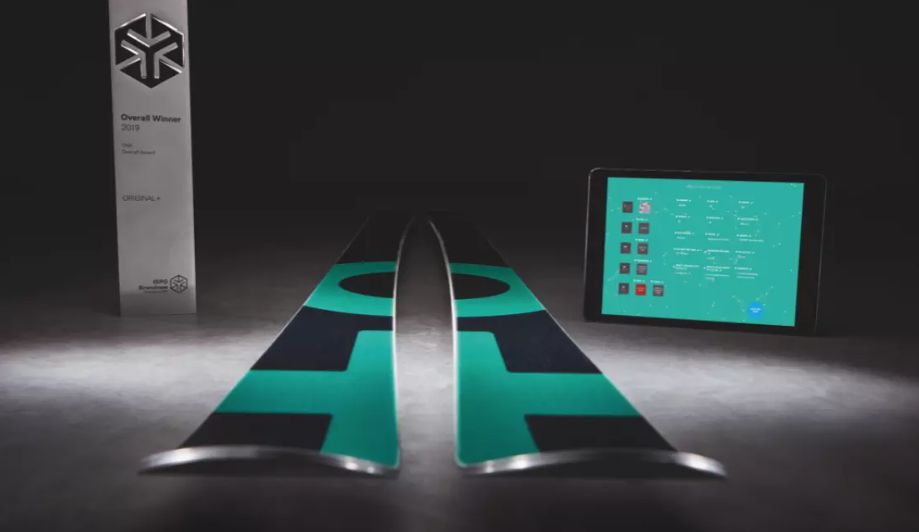

How ORIGINAL+ turns raw materials into high-performance skis

At ORIGINAL+, the work doesn't just start with selecting the best materials, it really starts there. Ski construction doesn't just mean precision, but also the interplay of craftsmanship, technology and passion. From the first cut to the final fine-tuning, every ski goes through a high-precision manufacturing process to guarantee maximum performance, durability and unique design.

The "Burger" Process: Layer by Layer to Perfection

At ORIGINAL+, a ski is constructed like an exquisite gourmet burger. Every layer has to be perfectly coordinated so that the overall package works.

- Wood core: The "patty" of the ski, made from selected types of wood to provide flexibility and stability.

- Reinforcement: Like the cheese that holds everything together. Fiberglass or other materials provide the necessary torsional rigidity and responsiveness.

- Cover: The sliding surface, made of high-density polyethylene to ensure optimal speed and durability.

- Top layer: protection and design. Influences not only the appearance but also the bending characteristics of the ski.

Did you know that at ORIGINAL+ we manufacture every single wood core in our own workshop from the best veneers and wood slats? This ensures a unique combination of flexibility and individual adjustment that no other manufacturer offers. This allows us to optimally adjust each core for strength, weight and performance, for a driving experience that is exactly right for you.

The fascinating thing about this process is that each layer is precisely coordinated and gives the ski its unmistakable dynamics.

Precise cutting with the Zünd G3 Cut Center

This is where the magic begins. The Zünd G3 cutter ensures that all materials are cut to the millimeter. Imagine you have to cut a puzzle and every single piece fits perfectly. This is exactly what this machine does with wood cores, bases and reinforcements. A perfect fit is the key to the final quality of the ski.

Individual design with the Roland RF640 Digital Printer

Performance is one thing, but a ski should also look great. With the Roland RF640 Digital Printer, we put long-lasting, razor-sharp designs on our skis. Whether minimalist and elegant or eye-catching and unique, every graphic is applied precisely to make the ski an eye-catcher on the slopes.

The special thing about this step is that each ski is unique and reflects the personality of the rider.

Handcrafted perfection: The soul of ORIGINAL+

Machines deliver precision, but it is the experienced hands of our ski builders that give the ski its soul. In our assembly station, the different layers are carefully assembled, aligned and checked by hand.

The cool thing about it is that this is the only way we can guarantee that each ski is individually tuned to the exact requirements of the rider.

Perfect connection with the Langzauner Ski Press

After the layers have been placed on top of each other, they go into the Langzauner Ski Press. Imagine all the ingredients for a perfect burger now being placed in the hot pan. That's exactly what happens here with the ski materials. Pressure and heat combine the components to form a single, stable unit.

The amazing thing about this process is that every pair of skis comes out of the press with absolutely consistent quality, regardless of the individual configuration.

Fine-tuning with the Reichmann DTS-U II Race

The last detail that makes the difference is the perfect edge grinding. With the Reichmann DTS-U II Race machine, the skis receive precisely ground, burr-free edges that ensure optimal grip and control on icy or hard slopes.

The best part of this step is the moment when raw materials are transformed into a fully functional, perfectly tuned ski.

Conclusion

At ORIGINAL+ we don't produce off-the-shelf skis, we create experiences. From the precise cutting with the Zünd cutter to the craftsmanship of our ski builders to the perfect finishing touches with the Reichmann edge grinding machine, every step is carried out with dedication, know-how and innovation.

What makes this entire process so special is that each ski is made with the rider in mind, from the first layer to the smallest detail.

Are you ready to feel the difference? Discover ORIGINAL+ skis and experience innovation, craftsmanship and performance in every turn. CONFIGURE YOUR ORIGINAL+ SKI HERE